Supply Chain Management

Innovation, transparency, and sustainability in supplier relationships.

Copel adopts integrated and sustainable supply chain management, aligned with ESG principles, ethics, integrity, and social and environmental responsibility.

This commitment is reinforced by three essential documents, which guide the relationship with suppliers and ensure that the entire chain is aligned with ESG principles, corporate governance, and current legislation.

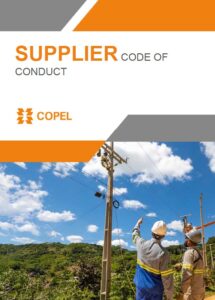

Supplier Code of Conduct

Published in 2025, the Supplier Code of Conduct defines clear standards of behavior and establishes guidelines that all suppliers and partners must follow in their business relationships with Copel.

It covers fundamental issues for sustainability, including:

- Respect for human rights and combating child and forced labor;

- Occupational health and safety;

- Environmental protection, pollution prevention, and efficient use of natural resources;

- Prevention and combating corruption, bribery, fraud, and anti-competitive practices;

- Data protection and privacy, in accordance with the LGPD.

Supplier Code of Conduct

The Supplier Manual serves as a practical guide, bringing together essential information on the technical, legal, socio-environmental, and integrity requirements that must be met by suppliers at all stages of their relationship with Copel.

The Manual is currently being revised to reflect the changes that are also being discussed in the Supply and Logistics Regulations, which are also being updated.

Among the topics covered are:

- Digital registration and approval via an integrated system;

- Operational procedures and contractual rules;

- Compliance with ESG criteria and sustainability practices;

- Communication and management of contractual obligations.

The Manual serves as a basis for suppliers to understand their responsibilities and act in accordance with the standards required by the Company, strengthening transparency and governance throughout the supply chain.

LGPD Guidance Booklet

In accordance with the General Data Protection Law (LGPD), Copel provides a booklet that guides suppliers on how to collect, process, and store personal data in an ethical and secure manner.

The booklet reinforces fundamental principles, such as:

- Transparency in the use of data;

- Guarantee of privacy and information security;

- Respect for the rights of data subjects;

- Rules for sharing, storing, and secure disposal.

Statement of Awareness and Commitment

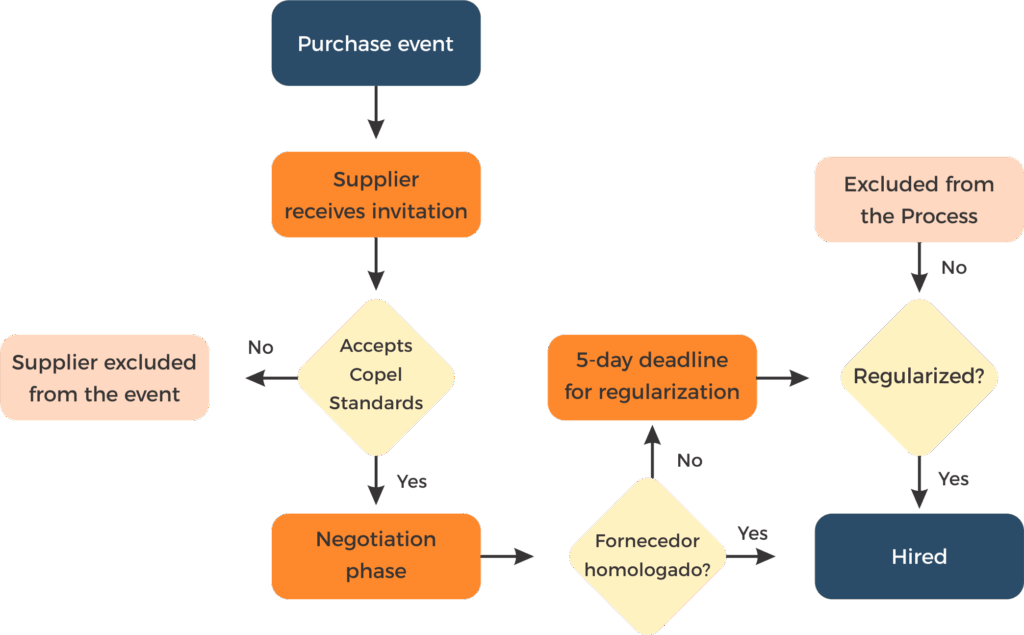

In order for suppliers to participate in purchasing events, they must digitally accept the documents that govern their relationship with Copel:

- Supplier Code of Conduct,

- Supplier Manual,

- LGPD Guidance Booklet.

This acceptance is the first screening criterion in the contracting process and ensures that the supplier is aware of and committed to:

- Ethical and transparent practices,

- Social, environmental, and governance (ESG) compliance,

- Protection and privacy of personal data.

This initial commitment directly influences the selection of suppliers, ensuring that only companies aligned with Copel’s values and strategic objectives move on to the next stages of negotiation, approval, and contract execution.

The Supply, Logistics, and CSC Department, linked to the Vice Presidency of Finance and Investor Relations, is responsible for establishing the guidelines and standards that guide supplier management at Copel.

This management is structured based on ESG principles, integrity, and innovation, ensuring transparency, efficiency, and alignment with the Company’s strategic objectives.

Its activities are structured into three macro-processes:

- Supplier Selection and Qualification – prior assessment of legal, technical, socio-environmental, and integrity requirements for entry into the supplier base.

- Supplier Evaluation and Monitoring – continuous monitoring of performance, compliance, and integrity during contract execution.

- Supplier Development and Relationship – actions aimed at strengthening partnerships and the joint evolution of the supply chain.

Strategic Alignment

Supplier Management is conducted in alignment with corporate strategies defined and approved by the Board of Directors (CAD).

Among the guidelines related to suppliers, the following stand out:

- Maintain discipline in capital allocation and technical rigor in asset management, project planning, and execution.

- Copel seeks not only to be a benchmark in its sector, but also to stand out for excellence in supply chain management through innovation, investment in technology, and workforce optimization.

- Strengthen the culture of safety, health, and quality of life at all stages of the supply chain.

This alignment extends to best market practices, strengthening performance with social and environmental responsibility and a focus on sustainability.

Continuous Review and Working Groups

Purchasing practices, contracts, and management methodologies are continuously reviewed to ensure they are up to date, innovative, and compliant with ESG requirements and best market practices.

These reviews are conducted by multidisciplinary teams, involving business, compliance, legal, management, and technology areas, formalized in specific working groups. These groups focus on adapting processes, updating contractual clauses, and integrating digital solutions, ensuring that Copel’s actions are always aligned with the Company’s strategic objectives and regulatory developments.

Internal Training and Development

Copel continuously invests in the development of its professionals, strengthening the ESG culture and encouraging the adoption of modern and innovative practices in supply chain management.

In addition to in-person training and events, the company offers the Corporate Supply Chain Academy, a digital platform with learning tracks focused on procurement, logistics, and related areas, supporting the continuous training of internal teams.

In recent years, several training initiatives have been promoted. In 2022 and 2023, workshops on Human Rights Due Diligence were held, marking the implementation of this practice in all of the Company’s activities. In 2024, Copel expanded the training of its employees through the Sustainability Course and ESG Integrated Week, reinforcing its commitment to ethics, social and environmental responsibility, and continuous improvement.

Copel conducts integrity assessments of suppliers and partners as part of the approval process, ensuring rigor, transparency, and compliance with best corporate governance practices.

This step was incorporated into the approval system (Linkana) in March 2025, providing greater agility and integration in the analysis process.

The assessment considers criteria such as company profile, relationship with the public sector, history and reputation, corruption prevention, conflicts of interest, ESG aspects, and compliance with the General Data Protection Law (LGPD).

After analysis, suppliers are classified into risk levels – low, medium, or high – allowing Copel to take appropriate actions, such as monitoring during the term of the contract or additional requirements to mitigate identified risks.

Based on this classification, the Compliance area guides the requesting area in the preparation of monitoring and mitigation plans, ensuring that, whenever possible, suppliers can correct irregularities through structured measures, maintaining strategic partnerships and preserving the integrity and interests of the Company.

Copel adopts strict criteria for hiring and approving suppliers, focusing on ethics, integrity, legal compliance, and ESG, strengthening the safety, quality, and sustainability of the supply chain.

The process occurs in two main stages: pre-selection and final selection, integrating digital practices, risk analysis, and corporate governance. This structure ensures that only suppliers that meet the required criteria are part of the Company’s supply chain.

Phase 1 – Pre-selection of suppliers:

During the contracting process, after consulting prices with potential suppliers, Copel performs standard ESG approval of the supplier, consulting data for legal, tax, and labor compliance analyses. In addition, standard ESG approval also includes an in-depth integrity assessment (background check). Depending on the type of object, economic-financial and/or technical analysis may be necessary.

In technical qualification, the requirements are specific to each type of material or service to be contracted. For products or services that have an environmental or social impact, certifications or attestations from the competent bodies are required, proving the product or service’s compliance with the required socio-environmental parameters. In addition, certificates of technical capacity issued by other companies may be required to attest to the experience and quality of the services or products covered by the contract.

Phase 2 – Supplier selection:

For the selection and hiring of the supplier, it is necessary that the supplier’s approval has been approved. If the company does not meet the integrity requirements or does not have any of the items required in the ESG-related qualification documents, a note is made in the process in the form of a negative recommendation for hiring.

Copel adopts a structured methodology to identify, prevent, and mitigate social, environmental, and governance risks in its supply chain. This approach considers both internal risks related to the Company’s own activities and external risks arising from the activities of suppliers and strategic partners.

Among the main risks monitored are:

- Environmental: greenhouse gas (GHG) emissions, origin of inputs, proper waste disposal, and compliance with environmental legislation.

- Social: respect for human rights, combating child or forced labor, adequate health and safety conditions, non-discrimination, and freedom of association.

- Governance: business integrity, prevention of corruption, bribery, conflicts of interest, and anti-competitive practices.

- Country risk: political, economic, environmental, and regulatory factors that may impact continuity of supply.

- Sector risk: characteristics specific to each type of activity or service contracted.

- Commodity risk: volatility in supply and demand, exchange rate dependence, land use, and intensity of natural resources used in production.

Definition and Types of Risks

During contracting, it may be necessary to prepare a Risk and Responsibility Matrix. This instrument defines the risks associated with each contract, establishes shared responsibility between Copel and suppliers, and guides the planning of preventive and corrective actions. The matrix considers the following aspects:

Impacts of Copel’s operations on society and the environment, which may generate regulatory and financial liabilities, in addition to affecting the Company’s reputation.

External impacts on operations, such as extreme weather events, scarcity of natural resources, health crises, community mobilization, environmental accidents, or geopolitical factors, such as country risk, which include economic instability, trade barriers, conflicts in strategic regions, specific commodity risks, and regulatory changes that may affect suppliers and global supply chains, potentially compromising the continuity of essential services.

This approach ensures that both direct risks related to Copel’s own activities and indirect risks arising from the actions of suppliers and strategic partners and global external factors are taken into account.

The results obtained through the matrix serve as a basis for guiding preventive and corrective actions, according to the criticality of the identified risks. When necessary, mitigation plans can be defined, with measures aimed at reducing impacts and strengthening supply continuity, always focusing on the integrity of the supply chain and the protection of the interests of the Company and society.

With the creation of the Supply Department in 2024 and the centralization of activities at the Holding Company, Copel structured an integrated methodology to identify, mitigate, and remedy negative impacts in its supply chain, focusing on ESG risk management – including human rights, environmental issues, health and safety, integrity assessment, and legal compliance.

In 2024, Copel had a total of 7,373 active suppliers, responsible for supplying materials and performing essential services in generation, transmission, distribution, and corporate activities, regardless of the existence of a contract. Of this total, 2,805 suppliers have signed contracts.

The supplier identification and classification methodology makes it possible to prioritize resources and efforts, ensuring that preventive and corrective actions are applied effectively, promoting greater transparency, safety, and sustainability throughout the supply chain.

Each year, Copel conducts a detailed analysis to identify its significant suppliers, those that, due to their size, criticality, or impact, require differentiated monitoring. This assessment considers both direct suppliers (level 1), contracted by Copel, and subcontractors (non-level 1), who operate through affiliated service providers.

Significant suppliers are classified into two categories:

- Critical due to their impact on the business.

- Critical in ESG.

The total number of significant suppliers in 2024 was 556, considering that some suppliers may simultaneously fall into both categories of criticality (business impact and ESG). In percentage terms, significant suppliers represent 19.82% of the total number of suppliers with active contracts and 7.54% of the company’s total number of suppliers, regardless of whether they have a contract. Below we describe what is considered in each criticality:

For business impact risk, Copel adopts a matrix that considers indicators such as Supplier Value and Availability, allowing it to identify those whose performance and continuity of supply represent the greatest strategic and financial risk to the Company. In 2024, 156 critical suppliers were identified in this group, representing 5.56% of the total number of suppliers with active contracts and 2.11% of the total number of suppliers.

For ESG criticality, Copel considers suppliers for which performance evaluations are carried out, as these are contract categories that are highly representative of the business. In addition to contractual criteria, risks associated with ESG aspects are identified, which guide actions such as training, technical guidance, and the provision of support materials. In 2024, 478 critical ESG suppliers were evaluated, representing 17.04% of the total number of suppliers with active contracts and 6.48% of the total number of suppliers.

In the procurement of materials, the most relevant risks in the categories assessed are related to integrity (including document compliance) and GHG emissions. In the procurement of services, labor, health, and safety risks stand out, especially in activities involving the handling of electricity. In other words, materials concentrate risks of logistical disruption and environmental impact, while services concentrate risks of accidents, reputation, and operational continuity. These factors, when combined with value and availability indicators, allow for the assessment of the risk of supply interruption and financial impact, ensuring the prioritization of mitigation measures.

Significant Supplier Identification Table | Values for 2022 | Values for 2023 | Values for 2024 |

| Direct Suppliers Evaluated | 8,069 | 8,787 | 7,373 |

Critical Suppliers by Business Impact* | 142 | 187 | 156 |

Critical Suppliers in ESG* | 142 | 187 | 478 |

Significant Supplier Expenses in relation to total | 11.91% | 6.25% | 25% |

Significant non-tier 1 suppliers | – | – | 377 |

*The total number of significant Level 1 suppliers in 2024 was 506. Some suppliers are classified simultaneously in both criticality categories — Business Impact and ESG.

Subcontractors

They act as outsourced service providers, linked to direct suppliers, and are therefore considered indirect suppliers (not Level 1).

Indirect suppliers (non-level 1) are also considered significant, since their hiring requires formal approval by the contract manager and they are subject to monitoring, document audits conducted by third-party management, and safety inspections. In other words, they must maintain the contractual and compliance conditions applicable to direct suppliers (level 1), with any non-compliance reported to their direct supplier (level 1). In 2024, 377 significant non-level 1 (indirect) suppliers linked to Copel’s direct contracts were identified.

Indirect suppliers also participate in engagement training. Starting in 2026, a sustainability assessment will also be sent to this audience, expanding risk management in the supply chain.

In 2025, the company took a step forward by adopting public ESG monitoring indicators, ensuring transparency and public comparability. Measurement began in 2025, and the first consolidated results will be published starting in 2026.

The indicators seek the following results:

- Expand the presentation of greenhouse gas emissions inventory by the group of suppliers critical to GHG emissions.

- Increase purchases from ESG-approved suppliers in relation to the volume of supplier spending.

- Expand sustainability assessment to a larger number of suppliers, including non-level 1 (subcontractors).

The targets set will be long-term with gradual progression so that by 2035, 100% of significant suppliers will be included in ESG indicator monitoring.

Copel maintains a structured supplier evaluation and development process, with public information accessible through its sustainability portal. This process aims to ensure that suppliers meet contractual and legal requirements and ESG principles, strengthening the value chain and promoting continuous improvement.

Supplier evaluation is carried out in two stages: documentary and field.

In the documentary stage, tax, labor, social, environmental, and integrity certificates and evidence are systematically verified through a digital platform that allows for continuous monitoring and administrative auditing.

In the field stage, Copel inspectors or hired consultants carry out second-party on-site inspections, including the Industrial Assessment (AVI), which verifies the supplier’s technical, manufacturing, and technological capabilities, quality control, and social and environmental practices.

These assessments follow best market practices and use recognized industry methodologies, such as compliance with Brazilian Standards (NBRs) and Regulatory Standards (NRs) on occupational safety.

When non-conformities are identified, specific plans are developed for correction, such as:

- Safety Risk Plan, focused on situations related to accident prevention, occupational health, and safety culture.

- Materials Quality Plan, designed to correct technical failures, traceability, and compliance of materials and equipment.

- Documentation Plan, to address irregularities in approval, non-compliance in third-party management, or contractual non-compliance.

These corrective plans are conducted jointly by the contract manager, the inspection area, and the supplier, with structured monitoring until complete resolution. When there is no progress or in critical cases, progressive penalties are applied in the following order: formal notification, fine, disapproval of approval status, and, finally, contract termination.

Once regularization is achieved, the supplier can participate in new purchasing events, passing all selection criteria.

| Supplier Evaluation Program Framework | Values for 2022 | Values for 2023 | Values for 2024 |

| Evaluated Suppliers | 422 | 312 | 478 |

| Percentage of Critical Suppliers | 14.79% | 49.73% | 85.97% |

| Suppliers with Negative Impacts | 70 | 93 | 14 |

| Suppliers with Action Plan for Improvement | 0* | 0* | 14 |

| Suppliers with Terminated Contracts | 3 | 4 | 0 |

*No contracts were terminated due to negative impacts.

In 2024, third-party management notified 416 suppliers that had submitted documents deemed non-compliant by the audit. A further 284 suppliers were notified of the risk of employee blocking due to lack of document regularization, resulting in 42 effective employee blockings. Once regularized, they are unblocked.

In 2025, with the creation of the Supplier Relationship and Development Division, centralized in the COE – Center of Excellence for Supply and Logistics, the mitigation and remediation procedure was improved, monitored by supplier and third-party management in conjunction with the contract manager and the supplier itself. In addition to the previous mitigation plan, a mechanism for partial payment blocking until regularization was implemented.

The measures are applied gradually and proportionally to the severity of the occurrence, as follows:

- Formal notification with a deadline for correction.

- Application of contractual penalties (such as fines).

- Partial blocking of payment until regularization.

- Rejection of approval.

- Contract termination.

Supplier Recognition

In 2025, Copel unified the supplier recognition programs, previously carried out separately by Copel Distribuição and Copel Geração e Transmissão, creating the Pure Energy Partner Award.

The purpose of the event is to recognize suppliers that have excelled in performance, sustainability, innovation, and safety, reinforcing their strategic partnership with the Company and encouraging continuous improvement throughout the supply chain.

This initiative consolidates best practices in recognition and certification, integrating technical, socio-environmental, and governance (ESG) criteria.

Award Criteria

Suppliers were evaluated based on:

- Technical and operational performance in the execution of contracts.

- Commitment to ESG practices, including integrity, human rights, and social and environmental responsibility.

- Innovation and technology applied to processes and services.

- Occupational safety and health, with a focus on prevention and continuous improvement.

Special Highlights: Sustainability and Workplace Safety

In addition to awards for technical performance and quality, Copel values suppliers who demonstrate best practices in sustainability and workplace safety, strategic areas for strengthening the supply chain.

- Sustainability: recognizes suppliers that adopt environmental, social, and governance (ESG) practices, including actions related to impact mitigation, GHG emissions inventory, and social responsibility.

- Workplace Safety: values suppliers that have excelled in accident prevention, maintaining safe work environments, and complying with the Company’s Safety Standards and Programs, with no records of serious or fatal accidents.

These recognitions reinforce Copel’s commitment to promoting an ethical, safe, and sustainable supply chain, encouraging continuous improvement and innovation.

The winners of the Pure Energy Partner Award were recognized during an event held in September 2025, for their performance in 2024, celebrating the partnership and the results achieved.

Pure Energy Partner Award 2024/2025 | |||

Categories | First Place | Second Place | Third Place |

Construction of power distribution networks up to 34.5 kV | CONSTRUCEL CONSTRUÇÕES DE OBRAS ELÉTRICAS | COOPERATIVA DE ELETRIFICAÇÃO RURAL DE CHOPINZINHO | PATOLUZ PROJETOS E INSTALAÇÕES ELÉTRICAS |

Distribution network maintenance | PUTON & DAL MOLIN | GLUZ INSTALAÇÕES ELÉTRICAS | RFM – SERVIÇOS ADMINISTRATIVOS |

Operational services | ENEL MANUTENÇÃO ELÉTRICA | ILUMINAR MATERIAIS ELÉTRICOS | CETEL CONSTRUÇÕES ELÉTRICAS |

Construction of Substations and High Voltage Distribution Lines | TECNOVA SOLUÇÕES | RGK CONSTRUÇÕES MONTAGENS E EMPREENDIMENTOS | ELETRO INSTALADORA K-LUZ |

Technical Works and Services for Generation | AQTECH ENGENHARIA E INSTRUMENTAÇÃO | GUIMARÃES MULTISERVIÇOS ENGENHARIA | AQUA GUARD SERVIÇOS ESPECIALIZADOS EM IMPERMEABILIZAÇÃO |

Technical Works and Services for Transmission | ENGERA CONSULTORIA, PROJETOS ELÉTRICOS & TREINAMENTOS | AEROSAT ENGENHARIA E AEROLEVANTAMENTOS | IM3 PROJETOS E SERVIÇOS |

Technical Works and Services in Renewable Energy | MS SERVIÇOS | CONSESPE ENGENHEIROS ASSOCIADOS | DOIS A ENGENHARIA E TECNOLOGIA |

Specialized Technical Services | SISTEMA DE TECNOLOGIA E MONITORAMENTO AMBIENTALDO PARANÁ | CENTRO DE PESQUISA DE ENERGIA ELÉTRICA | ALVARO JOSÉ NOE FOGAÇA |

Pure Energy Partner Award 2024/2025 | |||

Categories | First Place | Second Place | Third Place |

Electrical cables | CORDEIRO CABOS ELÉTRICOS | INTELLI INDÚSTRIAS DE TERMINAIS ELÉTRICOS | CONDUMAX |

Transformers | INDÚSTRIA DE TRANSFORMADORES ITAIPU | TRAEL TRANSFORMADORES ELÉTRICOS | – |

Manufacturers of poles | BERTOLINI INDÚSTRIA DE CONCRETO E METAL | M FLIPAK CONSTRUPAK MATERIAS DE CONSTRUÇÃO | A.M. KNAPP |

MRO Materials – GET | TECNOVA SOLUÇÕES | RGK CONSTRUÇÕES MONTAGENS E EMPREENDIMENTOS | ELETRO INSTALADORA K-LUZ |

Sustainability and Workplace Safety | |

Sustainability – Micro and Small Businesses DIS | GIARETA BORBA INSTALAÇÕES ELÉTRICAS |

Sustainability – Medium and Large Size DIS | CONSTRUCEL CONSTRUÇÕES DE OBRAS ELÉTRICAS |

Occupational Safety DIS | C C E CAGNINI CONSTRUÇÕES ELÉTRICAS |

Sustainability – Micro and Small Businesses GET | DRAXOS CONSULTORIA E GESTÃO AMBIENTAL |

Sustainability – Medium and Large Size GET | SAE TOWERS BRASIL TORRES DE TRANSMISSÃO |

Occupational Safety GET | AQUA GUARD SERVIÇOS ESPECIALIZADOS EM IMPERMEABILIZAÇÃO |

History of Previous Editions

Learn more about previous editions, certificates, and winners of awards held separately.

Access the history of previous awards: Copel Distribuição and Copel Geração e Transmissão.

Supplier access to ESG references

The recognition of suppliers through the Pure Energy Partner Award is not limited to the award itself, but also serves as a catalyst for disseminating good practices throughout the supply chain. Based on highlights in sustainability, occupational safety, and innovation, Copel expands suppliers’ access to ESG references by promoting training, sharing experiences, and providing content that allows everyone to evolve based on real examples of excellence.

Sustainable Supplier Management is one of the material topics for Copel. Therefore, sharing ESG references with this audience is a relevant and strategic activity for the Company. During training sessions for suppliers, new developments, success stories related to the topics discussed, as well as lessons learned by Copel are presented. A significant portion of the training offered covers ESG topics, taught by internal and guest experts, allowing suppliers to update and expand their sustainable practices.

Copel periodically conducts a sustainability survey with its suppliers to map their needs, expectations, and sustainability actions. This constant dialogue strengthens the relationship with the chain and allows for the improvement of training and engagement programs.

It is worth noting that the materiality process, which defines the priority issues for Copel, involved extensive consultation with all stakeholders, including suppliers, in order to understand the priorities perceived by those who affect or are affected by the Company.

Through these actions, Copel ensures that its suppliers receive clear information, ongoing training, access to references, and structured support, strengthening an ethical, safe, and sustainable supply chain, connecting knowledge, continuous improvement, and public recognition.

Supplier Development

The transfer of knowledge, technologies, safety practices, management and socio-environmental responsibility aims to build and maintain an increasingly capable and sustainable supply chain.

Supplier Management at Copel Generation and Transmission

At Copel Geração e Transmissão, Supplier Management contributes to sustainable development by improving the management of the production chain and optimizing resources for the benefit of the community.

Aligned with the best management practices, the Certification Program and the Supplier Development Program at Copel GeT seek to promote recognition and help suppliers improve their performance in the environmental, social and economic dimensions.

Supplier Management at Copel Distribuição

For Copel Distribuição, suppliers are strategic partners, since they are suppliers of inputs (materials, equipment and services) that are indispensable for the Company’s business.

Copel Distribuição uses as main criteria in contracting suppliers, compliance with labor legislation, respect for human rights, fiscal integrity and environmental responsibility. The criteria are defined in the bidding notices, contractual clauses, supplier registration manuals, code of conduct, in addition to standards and technical manuals permanently available to interested parties on the organization’s website.